Seeds Are Alive

Why We Still Pack by Hand

We often hear the question: “Why don’t you just buy a machine?”

It’s a fair question. A machine is faster. A machine doesn’t get tired. A machine doesn’t need coffee breaks. But a machine also doesn’t look at or feel the seed it counts.

For us, packing by hand isn’t about nostalgia. It is a deliberate operational choice to prioritize viability over velocity.

When you automate seed packing, machines treat the seed as inventory—a unit to count, fill, and seal as quickly as possible. But a seed is a living embryo. It is alive, breathing (very slowly), and waiting. Because we view ourselves as stewards of that living potential, we handle it differently.

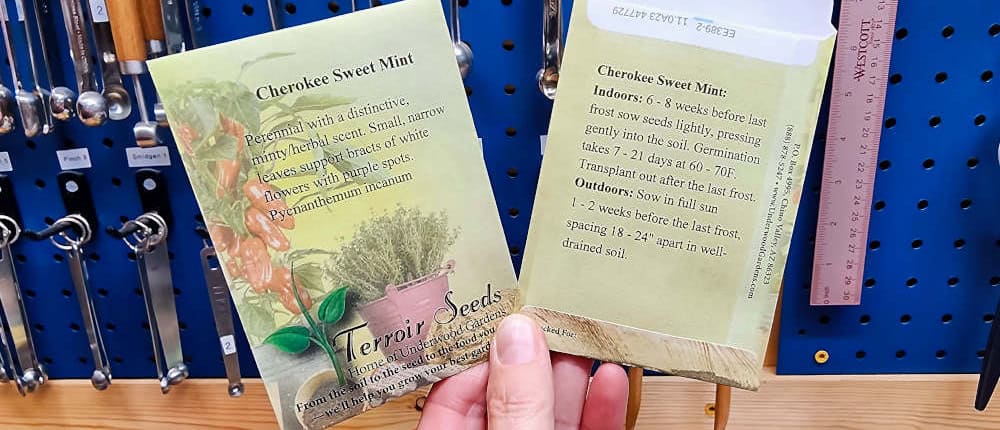

Seed packing tools ready to go

The Purity Protocol

A human hand fills every single packet that leaves our warehouse. This allows for a level of quality control that no sensor can match.

First, we perform a visual check. A human eye spots the cracked bean or the shriveled pea that a machine would blindly seal. We catch the defects before they become your problem.

Second, we maintain absolute purity. Industrial packing machines are complex beasts with hidden crevices, chutes, and hoppers. To ensure zero cross-contamination between varieties, an operator must completely disassemble, clean, and inspect the machine between every single batch—a process that takes hours.

In the industrial trade, “close enough” is often the standard. We cannot risk a stray Jalapeño seed ending up in your Bell Pepper packet. By packing by hand, we ensure your Honkin’ Big Black Cherry packet contains only that variety, with no stragglers from the previous run.

Packing seed with a custom-made scoop

The Living Variable

In the seed world, size is a study in extremes. A single packet of beans might hold 25 seeds that feel like marbles, while a packet of flowering tobacco holds dust-like specks that number in the hundreds.

The challenge goes deeper than variety variance. Because seeds are living things grown outside, their size changes from year to year based on the weather, moisture, and soil conditions of that specific season. A tomato seed from a dry year might be smaller than one from a wet year.

A machine struggles to handle this variance without crushing the delicate ones or miscounting the large ones. We can’t just “set it and forget it.” We recalibrate our approach for every new lot of seed that arrives.

To solve this, we rely on a surprisingly low-tech, highly specialized toolkit.

We craft custom scoops for our tiniest seeds one at a time. We use a precision drill press to machine the cup, slowly making microscopic increases in depth, stopping frequently to test the seed count until it is reliably accurate. This allows us to consistently measure hundreds of tiny seeds without ever damaging a fragile seed coat.

This manual process also allows us to operate on a “Generous Average.” Industrial machines are programmed to hit a minimum viable count to maximize profit margins. We calibrate our scoops to ensure we meet the minimum count, which usually means the actual count in your packet is slightly higher. We would rather you have a few extra seeds than fall short.

Filled paper seed packets in a controlled environment

The Sanctuary

The Rule of 100

Before the seed ever reaches the scoop, its environment is everything. Long before we start packing, our bulk seed lives in a climate-controlled environment where we maintain stable cool temperatures and, crucially, low humidity.

Seed longevity is a math equation, often referred to in the trade as the “Rule of 100.” The rule states that the sum of the storage temperature (in Fahrenheit) plus the percentage of relative humidity must be equal to or less than 100 to keep a seed viable for the next planting season.

For example, if a room sits at 75°F with 50% humidity, the total is 125.

That seed is dying. By strictly stabilizing our environment to stay well below that threshold, we keep the seed’s metabolic rate low, essentially “sleeping” deeply until it is time to wake up in your soil.

Printed paper seed packets

The Package

Why We Choose Paper

This brings us to the final aspect of our process: the packet itself.

You may have noticed a trend toward “space-age” packaging, where vendors sell seeds in nitrogen-flushed Mylar, vacuum seals, or even frozen glass vials. While these methods mimic professional gene banks, they often fail the home gardener.

A professional gene bank is a controlled laboratory. Scientists dry seeds to dangerously low moisture levels (3-8%) before sealing them. If a home gardener tries to mimic this by freezing seeds in sealed glass or plastic without that lab-level drying, temperature fluctuations in the mail or the home create condensation inside the container. Since glass and plastic don’t breathe, that trapped moisture leads to rot.

We choose high-quality paper packets because they act as a buffer. Paper breathes. It allows for a microscopic exchange of air, maintaining an equilibrium with the ambient environment. For the season-to-season storage typical of a home gardener, this prevents the “greenhouse effect” and keeps the embryo dormant but safe.

3D printed mini scoops

From Our Hands to Yours

There is a profound difference between receiving a packet stamped by a mechanical hopper and receiving one measured by a person who knows exactly what that seed will become.

We choose this way because gardening itself is a human-scale act. You don’t garden by algorithm; you garden by observation and care. We believe your seeds deserve the same treatment.